Extreme flexibility with load variations. The system is insensitive to large variations (plus or minus) in both biological and hydraulic load, even if they last for many hours.

Biorulli® Biological Oxidation System

for biological wastewater treatment

An efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as “biological disc rotors,” has very low operating and maintenance costs.

Modularity and scalability. Facilities can be upgraded at later times by adding additional units.

Low energy use. The system works mechanically. Consequent lowering of operating costs.

Rapid, mechanical starting. The system starts up in a short time (10÷15 days) without the need for inoculation of bacterial flora.

Compactness and adaptability. The small size allows in different spatial configurations.

Ease of operation and maintenance. The purely "mechanical" operation of the machine does not require specialized personnel. The wear and tear of mechanical parts is negligible, the administration of additives or reagents is not expected.

Biorulli® oxidation system: description and operation

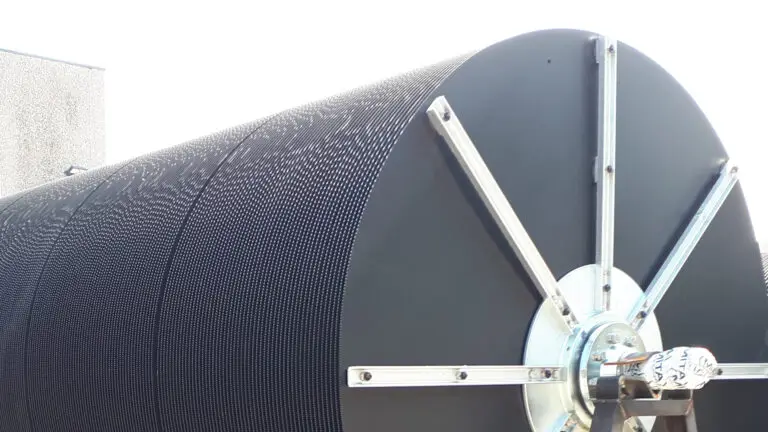

The Biorulli® biodisc biological oxidation system uses one or more rotating rollers to break down the organic matter contained in wastewater. It is an aerobic biological treatment system: oxygen, and the aerobic bacteria that derive “nourishment” from oxygen, play an important part in the decay of pollutants in civil or industrial wastewater.

Biodiscs are also called “biological disc rotors” or even “rotating biological contactors“.

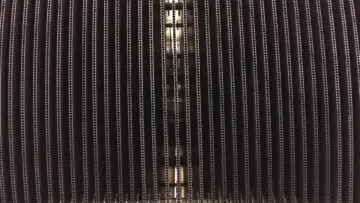

In the Biorulli® oxidation system, biodiscs are fixed on a central shaft in varying numbers depending on the model. By means of a gear motor, the shaft is turned very slowly (1 ÷ 5 revolutions per minute, depending on the model and the characteristics of the effluent). The disks, made of propylene, are partially immersed (about 40 percent of their diameter) in a tank through which the effluent to be purified flows.

It is precisely the contact between effluent and biodiscs that encourages the formation of bacterial flora on the propylene (plastic material) surface of the discs.

The flora, thanks to the continuous rotation of the discs, is alternately immersed in the sewage and brought into contact with the air: in the first phase it takes up the organic matter necessary for its nourishment, and in the second it becomes saturated with oxygen, a fundamental element of the biological oxidation process and thanks to which the bacteria themselves carry out the aerobic process. The layer of bacterial flora, having exhausted its life cycle, then independently detaches itself from the surface of the biodiscs in the form of easily sedimentable flakes.

Do you need info?

We would like to support you with our technologies: we are always happy to forward you technical information, explanatory materials, and bid requests.

Ask for InformationDownloads

Components of Biorulli® Biodiscs

Plastic Discs

They are immersed for a little less than half (40%) of their diameter in a tank containing the sewage to be purified. They are attached to the central shaft, which is rotated. On these rollers the bacterial flora necessary for the biological oxidation process is fixed.

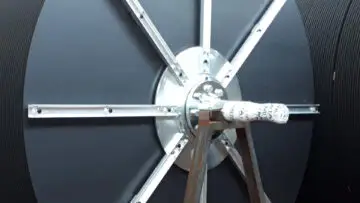

Central shaft

Discs of plastic material are attached to it. It is rotated by a gear motor at a speed between 1 and 5 revolutions per minute.

Basic Version

Backwash works with only one pump at a time-an additional energy saver.

Our range of Biorulli®

Biorulli® Biodiscs Monoblock M 115

Efficient, compact, extremely flexible with different pollutant loads: the Biorulli® biological oxidation system, monoblock M 115 series, is ideal for biological water treatment in apartment buildings, villas, small campsites, and factories.

Biorulli® Biodiscs Monoblock M 200

An intermediate-sized version of the one-piece biodiscs, the M 200 series is suitable for hotels, villages, small communities, and industries. Tank optionally made of treated and painted carbon or AISI 304-316 stainless steel. Efficiency and extreme ease of installation.

Biorulli® Biodiscs Monoblock M 240

It is the monobloc version, thus consisting of rollers and tank, with larger dimensions, useful for plants with more important disposal needs: nevertheless, M 240 biodiscs feature the same simplicity of installation, operation and maintenance typical of biological treatment solutions offered by MITA Water Technologies.

Biorulli® Biorotors B 200

The disc rollers, B 200 series, are the Biorulli® biodiscs biological oxidation solution: allowing high versatility in the face of widely varying effluent loads throughout the year. All this in conjunction with truly affordable acquisition costs.

Biorulli® Biorotors B 240

B 240 series biorotors are a cost-effective version for medium-sized biodiscs for biological treatment of industrial and civil wastewater to be installed in concrete tanks. Small footprint and easy and simple installation.

Biorulli® Biorotors B 290

A solution with large-diameter biodiscs for sizable plants, but with the same simplicity of installation, operation and maintenance as all Biorulli® rotating biological contactor series: these are the Model B 290 Disc Rollers.

CB 200 – CB 240 Covers

Biorulli® covers of this type can be requested by customers for biodiscs installed in concrete tanks.Some MITA Projects with Biorulli®

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Biorulli® Biodiscs

- Lamellar Pack Decanters

- Food & Beverage Industry

Biodiscs and Decanter for Italian Food Company

Integrated systems for different stages of water treatment: the key to a successful supply for a food company, through an environmentally sensitive engineering consulting firm in northern Italy.

Read more- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Biorulli® Biodiscs

- Continuous Sand Filters

- Oil & Gas

Biodiscs and Sand Filters for Coastal Depots of Esso

MITA Water Technologies provided ESSO Italiana with wastewater treatment solutions at the coastal depots in Naples and Palermo. Through the use of continuous regeneration sand filters and Biorulli(r) biodiscs, significant results were achieved, such as reduced energy consumption and maintenance costs, plant modularity, and compliance with current regulations.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreHotels

Our systems can be applied to both hotel facilities with seasonal and annual activities.

The characteristics of Biorulli® are most exploited in the first case (campgrounds, resorts) but in general they respond very effectively to the needs of the sector. In fact, it is always advisable to have plants that are ductile under all loading conditions, both hydraulic and biological, and with the least possible manpower for maintenance and operation.

Compared with other alternative biological purification systems, the biodisc system is less noisy and, because it is compact and can be buried and covered or enclosed within a building, has a better environmental impact.

Airports

This is one of a variety of areas where Biorulli® have been installed over the past few years.

Sometimes, given the predisposition of Biorulli® to biologically degrade small amounts of hydrocarbons, it is possible to treat sanitary water together with apron (storm) water.

In the latter circumstance, good upstream de-oiling of the Biorulli® is essential.

They are also valued for their compactness, modularity (allowing easy plant expansions) and the possibility of repositioning.

Hospitals

The absence of aerosols, and thus of the danger of bacterial contamination of the air, is certainly the most attractive feature of Biorulli® for this type of installation, especially when the system is in the vicinity of the hospital unit.

Compared with other alternative biological purification systems, the biodisc one is also less noisy and, thanks to its compactness and the possibility of burying and covering it or enclosing it within a building, has a better environmental impact.

Highway Service Areas

This is one of the applications for which the largest number of installations have been carried out.

In fact, one of the most important features of biodisc systems is the system’s extraordinary ability to adapt to fluctuations, both in terms of flow rate and composition of the slurry to be treated, which are often very large in a service area.

In particular, in the face of underloading, the system reacts spontaneously without backlash.

In contrast, in plants previously designed and built with activated sludge technology, the organic matter shortage that occurs in the face of underloading caused the process to stall.

Additional advantages offered by the Biorulli® are the low maintenance required and little control by refuelers. Finally, the compactness of the biodisc plant and its scalability make it ideal for this type of installation.

Alpine Refuges

The plant must be located indoors and in small spaces. In addition, the flow rate of sewage to be treated is extremely discontinuous, and it is normal that, during off-season periods, there may not be any at all for several days.

The biodisc system is the ideal system for this type of installation: it is extremely compact, can be placed indoors, and has an extraordinary ability to adapt to fluctuations, both in terms of flow rate and composition of the effluent.

Neither an activated sludge system (space and risks from underfeeding; organic matter deficiency, which occurs precisely in the face of underloading, can cause it to block) nor a percolator (space and elevation) is therefore conceivable.

The low electrical power requirements combined with low consumption make it possible to be powered by energy produced from alternative sources (e.g., photovoltaic panels).

Resorts and Campgrounds

In the worst cases, the plant is operational for three or four months of the year with increasing (June to August) and decreasing (August to September) inflow.

The only biological purification system that, sized for maximum capacity, can operate under all conditions and without corrective action is certainly the Biorulli® system.

In addition to this, it is then essential to have a process that is triggered as quickly as possible upon the influx of the first users or, even, service personnel before opening.

Civil Discharges from Establishments

In this application it is necessary to opt for flexible systems that are not affected by weekend breaks or vacation periods.

There is almost always an equalization phase to laminate even partially the flow rate that is normally discharged in 8 to 9 hours. It is then very important to have a technology that requires very little maintenance and control and can be operated even by unskilled personnel.

The Biorulli® system offers undoubted advantages over other alternative biological purification systems:

- extraordinary ability to adapt to fluctuations, both in terms of flow rate and composition, of the sewage to be treated;

- low installed power and low energy consumption (for the oxidation phase: up to 5-10 times less than alternative systems);

- low maintenance time and ease of operation;

- modularity as the population served increases;

- low noise and absence of aerosols.

Collective Canteens

Treatment with Biorulli® is normally proposed because of its ease of management and control in situations where personnel are scarce and unqualified.

The flow rate obviously needs to be equalized since water is discharged only 3/ 4 hours per day. Unlike other biological procedures, Biorulli® do not suffer if not fed for long periods (weekends, vacations, etc.).

Essential is good pretreatment against fats and solids.

Small Communities

The optimal range for the use of Biorulli® in municipal drains is between 30 and 5,000 population equivalents, although installations below and above this range have historically been performed.

In communities with high tourist fluctuations, low energy availability, staff shortages, potential for future increases, proximity of the plant to the population center, etc., the Biorulli® system offers undoubted advantages over other alternative biological sewage systems:

- extraordinary ability to adapt to fluctuations, both in terms of flow rate and composition, of the sewage to be treated. In particular, in the face of underloads the system reacts spontaneously without experiencing setbacks, unlike what can happen with plants with activated sludge technology;

- low installed power and low energy consumption (for the oxidation phase: up to 5-10 times less than alternative systems);

- low maintenance and operating costs;

- scalability as the population served increases;

- low noise and absence of aerosols.

Research Expeditions

An unusual use of Biorulli® was chosen, and is still being adopted, by the Italian (ENEA) expedition to Antarctica.

The plant serves about 60 people and is placed inside containers (heated, of course); it is activated in October and remains in operation until February. The request was for an elastic plant that was easy to start up and operate and could withstand a certain salinity of sewage resulting from the use of seawater for toilets.

The biodisc system fully meets these requirements. In addition, the low electrical power required and low consumption make it possible to power the Biorulli® with energy produced from alternative sources (e.g., photovoltaic panels).

The application of this system has characteristics akin to those installed to serve mountain huts.

Sports Centers

May include swimming pools, tennis courts, golf courses, stadiums, etc. Flow rates are always very discontinuous throughout the day and often only for a few days a week. It is therefore necessary to have a system that can operate under different conditions without having to make corrections to the system.

One of the most important features of biodisc systems is precisely the extraordinary ability of the system to adapt to fluctuations, both in terms of flow rate and composition, in the slurry to be treated. In particular, when faced with underloading, the system reacts spontaneously without being affected; on the contrary, in activated sludge technology plants, the shortage of organic matter, which occurs precisely when faced with underloading, can cause them to block.

Inclusion in particular natural environments is also a reason for preference for the Biorulli® system, which is appreciated for its compactness and the possibility of partially burying and covering it or enclosing it within a building.

MSW Landfill Leachate

This can be considered a “municipal” application, although biological treatment alone is not enough to carry out complete depuration. It is normally supplemented by a chemical-physical phase and other pre- or post-treatments.

Given the unpredictability and variability of the water to be treated, Biorulli® offer greater guarantees than other biological systems, even in the event of “shock” or poisoning. They have an extraordinary ability to adapt to fluctuations in discharges, both in terms of flow rate and composition; moreover, the process is triggered very quickly.

Pharmaceutical Industries

We have carried out some important installations in this sector, including some large ones (16 rollers each having a diameter of 2.90 m).

In these cases we are dealing with water that is very loaded with pollutants, and Biorulli® are not the only step in the purification process. The organic substances to be degraded are usually solvents, alcohols, esters, and aldehydes.

The use of Biorulli® has the advantage of taking up less space and being more adaptable to changes in influent characteristics, an extremely useful aspect when production undergoes cyclical changes.

Compared with conventional activated sludge systems, Biorulli®s highlight their simplicity of operation and control, which translates into less need for specialized personnel to manage the treatment plant.

Oil & Gas Industry

Both refineries and fuel depots are part of this sector.

Since specific articles are known in the literature on the abatement of oils, hydrocarbons and phenols with biological biodisc treatment, this is the industrial sector where the first installations of our system were carried out and where we have the most references.

The water to be treated is both process water (in the case of refineries) and rainwater, tank drainage and “clearing” water (in the case of storage facilities).

A further motivation for using Biorulli® instead of other biological technologies is the discontinuity of discharge, especially where stormwater is treated; as we know, Biorulli® do not suffer even if they are not fed for long periods.

As in most industrial applications, Biorulli® are preceded and followed by other treatment steps; nutrient dosing is always provided for proper functioning of the biological process.

Dairies

The water to be treated is particularly biodegradable, and often characterized by high loads. Depending on the size of the production facility or the type of limits to be met at discharge, Biorulli® can be used as the sole treatment or combined with other biological system.

Typically, this involves roughing with Biorulli® and finishing with activated sludge. In the former case, the simplicity of plant management and operation, which is essential in small settlements, is emphasized; in the latter case, the predisposition of Biorulli® to operate even at high specific influent loads.

Compared with traditional systems, the Biorulli®s highlight their compactness, modularity (which makes possible possible expansions at later times), low energy consumption, and simplicity of management and control, which translates into less need for specialized personnel.

Textile Industries

Predominantly used in dyehouses, Biorulli® have also been used in printing mills, woolen mills, felting mills, etc.

The key parameter to be degraded in most cases is surfactants, particularly nonionic surfactants. Although it is known that in biological oxidation at Biorulli® the retention times are not high, excellent percentage abatements of these pollutants have been equally found.

Their small size, ease of operation and low energy consumption are the reasons why they are often preferred to alternative biological purification systems.

Another advantage offered by this system is the significant reduction in the phenomenon associated with foam formation, made possible by the low velocities involved and the absence of air insufflation.

Slaughterhouses

These are facilities with particularly pollutant-laden water, even where blood is recovered; hence the need to have several stages of treatment.

Biorulli®, as is the case in the dairy sector, are often used as the first biological roughing stage, followed by an additional biological oxidation-nitrification stage.

Slaughter activity is often sporadic (a few days a week) and for a few hours a day; hence the need to have a system that is always active, even if it does not receive influent for days, such as that in Biorulli®.

In addition, slaughterhouses often require a system that occupies the smallest possible space and requires the simplest operation: the biodisc technique largely satisfies both needs.

Confectionery Industries

Confectionery industries can be of a variety of types. Our installations refer to industries that produce baked desserts (cookies, panettone, etc.).

Biorulli®, often combined with other technologies, offer guarantees of smooth operation as different seasonal productions vary by virtue of their flexibility and elasticity.

The modularity of the system, which allows for easy expansions, coupled with the simplicity of operation, has prompted several companies and designers to use this solution.

Laundries

Comparable at times to those in some textile industries, the plants are directed at degrading surfactants and organics from different types of washed items (restaurants, hospitals, etc.).

Biorulli® are proposed because of the ease of operation and low supervision required, with no need for specialized personnel.

Since no additives are required (as in chemical-physical treatments), the cost of operation is significantly low. The small space occupied by the Biorulli® section and the fact that they can be placed in a wide variety of sites has encouraged consistent development of the system, especially in small and medium-sized laundries.

Wine Industries

The purification of wastewater from these companies is not easy to implement, especially considering that for a couple of months a year (harvesting and racking) organic loads can be more than ten times the annual standard.

In these cases, an excellent solution is to provide an organic system in Biorulli®, operating year-round and a supplement (organic or not) for the peak months. Doing so results in very low energy consumption for much of the year and a very simple control of the plant.

Paper Mills

The choice of plant type is influenced by the size of the paper mill and the lower or higher closure of the production cycle (percentage of upstream recycling), which determines the concentration of the influent at the treatment plant.

Biorulli® are mainly adopted in cases with low or medium COD concentrations (more open cycles) or as finishers, downstream of another process, in cases with high concentrations (more closed cycles).

In both cases, Biorulli® are preferred because of their small footprint and because they do not require specialized personnel to run them.

In mills that process waste paper, an additional advantage is the ease of adaptation to the different types of resulting discharge.

Chemical Industries

The waters to be treated are more or less traceable to those of the pharmaceutical industry, which is a related industry. The companies involved are those that produce substances derived from organic synthesis and therefore very often biodegradable.

Biorulli® are widely used especially in the abatement of hydrocarbons, alcohols, esters, etc.; for these substances the “performance” compared to other biological processes is more evident.

In this area, Biorulli® also offer their ease of adaptation to the various types of the discharge that changes according to the production of the moment.

Among the advantages of Biorulli® should always be mentioned the smaller space occupied and ease of management.

Animal Breeding

The process varies depending on the kind of animals raised. There are no major problems for cattle, sheep and chickens, while in the case of pigs, combined and highly exaggerated systems are required to fall within legal limits.

The simplicity of management and the little supervision required place Biorulli® technology as the first with which to compare.

In some cases they are used only as a roughing treatment since no restrictive limits on discharge are required.

Would you like a noncommittal consultation?

Tell us about your project in wastewater treatment or tertiary filtration.

Contact us now