Water Treatment Products

Industrial and civil wastewater treatment technologies

Simplicity, reliability ... and the lowest product life cycle cost: water treatment solutions from MITA Water Technologies cover all stages of purification, with a focus on selecting cost-effective, easy-to-manage technologies. A response to stakeholders from both the civil and industrial sectors.

Biorulli® Biological Oxidation System

Biorulli® Biological Disc Rotors Monoblock M 115

Efficient, compact, extremely flexible with different pollutant loads: the Biorulli® biological oxidation system, monoblock M 115 series, is ideal for biological water treatment in apartment buildings, villas, small campsites, and factories.

Biorulli® Biological Disc Rotors Monoblock M 200

An intermediate-sized version of the one-piece biodiscs, the M 200 series is suitable for hotels, villages, small communities, and industries. Tank optionally made of treated and painted carbon or AISI 304-316 stainless steel. Efficiency and extreme ease of installation.

Biorulli® Biological Disc Rotors Monoblock M 240

It is the monobloc version, thus consisting of rollers and tank, with larger dimensions, useful for plants with more important disposal needs: nevertheless, M 240 biodiscs feature the same simplicity of installation, operation and maintenance typical of biological treatment solutions offered by MITA Water Technologies.

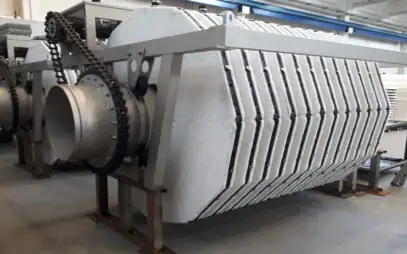

Biorulli® Biorotors B 200

The disc rollers, B 200 series, are the Biorulli® biodiscs biological oxidation solution: allowing high versatility in the face of widely varying effluent loads throughout the year. All this in conjunction with truly affordable acquisition costs.

Biorulli® Biorotors B 240

B 240 series biorotors are a cost-effective version for medium-sized biodiscs for biological treatment of industrial and civil wastewater to be installed in concrete tanks. Small footprint and easy and simple installation.

Biorulli® Biorotors B 290

A solution with large-diameter biodiscs for sizable plants, but with the same simplicity of installation, operation and maintenance as all Biorulli® rotating biological contactor series: these are the Model B 290 Disc Rollers.

CB 200 – CB 240 Covers

Biorulli® covers of this type can be requested by customers for biodiscs installed in concrete tanks.Biocombi Compact Plants

Biocombi Monoblock BC 2

Biological oxidation and efficient depth filtration are typical features of the Biocombi Monoblock BC 2, an integrated and compact wastewater treatment system for small communities. It is a suitable solution for low water flow rates while being able to withstand significant load increases at certain times of the day and year.

Biocombi Monoblock BC 4

Biocombi compact plants are efficient and cost-effective solutions for wastewater treatment in small communities. These systems integrate several steps of purification into one tank, with the Monoblock BC 4 version including biodiscs for biological oxidation and two drum filters in a horizontal version for secondary sludge separation. The filtering surface area is double that of the BC 2 version: high effluent quality, even in situations of variable loads, while still having a very small footprint.Pile Cloth Filters

Drum Filters TF – TF VM

The high filtration rates and small footprint make the Drum Filter the ideal final filtration system for sewage treatment plants, industrial or municipal plants of small capacity. All units are complete with an electrical control panel and can be installed in a concrete tank or supplied complete with a metal containment tank.

Disc Filters PEC – PEC VM

With these free-fiber filtration systems, we get to serve medium to large sewage treatment plants with minimal floor space requirements. Not only that. In the PEC and PEC VM disc filters, backwashing with sequentially driven pumps provides the machine with operational continuity in water treatment, consequently avoiding the need to provide a back-up unit.

Disc Filters PPC – PPC VM

A solution for high filtration yields and efficient handling and backwashing, with only two pumps for the whole system: the PPC and PPC VM disc filters are for concrete or metal tank, respectively. Versatility and little ancillary work required for operation.

Vertical-Axis Disc Filters PECV VM

An optimal solution for small and medium-sized plants, as much for its compactness as for its simplicity of installation and operation: these are the PECV VM metal tank vertical axis disc filters, for the final separation of suspended solids from civil and industrial wastewater.Filtrasand Continuous Sand Filters

Flowpack Lamella-Pack Decanters

Flowpack Lamellar Decanters with F Frame

They are a solution consisting of the parallel-channel lamellar pack only. F-frame Flowpack lamellar decanters are usually used for upgrading existing settlers or for housing in concrete tanks.

Flowpack Lamella Decanters Monoblock FM

Solid-liquid separation, sludge decanting, water clarification for further finishing operations-all these are represented by the FM Monoblock Series lamella decanters. Compact, efficient and space-saving solution. Simplicity of operation and very low product life cycle costs are pluses appreciated by customers in the civil and industrial fields.Oilpack Lamella-Pack Oil Separators

Oilpack Oil Separators with O-Frame

MITA Water Technologies offers an oil separation option with only lamella pack enclosed in a stainless steel frame. This system can be installed in existing tanks or in new specially made tanks, resulting in a complete oil separation system.

Oilpack Oil Separators Monoblock OM

These one-piece oil separators are designed to separate non-emulsified oils and consist of a containment tank, made of treated and painted carbon steel or AISI 304 stainless steel or stainless steel according to the customer's choice, and a 45° inclined parallel channel lamella pack made of UV-resistant polystyrene. Customizations with special materials are available upon request.Dissolved Air Flotation Units

Mitadaf MD Dissolved Air Flotation Units

Mitadaf is the dissolved air flotation (DAF) system developed by MITA Water Technologies. Its outstanding efficiency in separating solids from liquid and thickening sludge comes from a unique approach that combines the use of microbubbles of air, produced by our Mitasat MS, with a uniform effluent hydrodynamic system.

Mitasat MS Microbubble Reactor for Flotation Units

The Mitasat reactor is a key component of the dissolved air flotation process, with high efficiency in the generation of microbubbles of air and no need for excess air release valves. Made of AISI 316 stainless steel and certified according to pressure vessel regulations, it is used in civil and industrial biological plants for sludge clarification and thickening. It is also ideal for oxygenation in activated sludge biological plants and performance improvement in existing flotation plants.Filling Materials

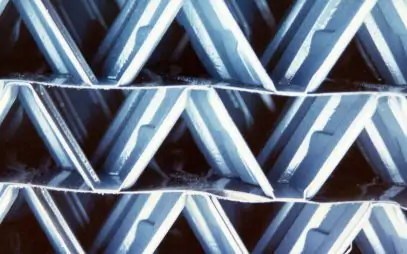

Bioset Biofilm Filling Materials

Bioset biofilm media consist of lightweight and robust PVC modules that provide a high active surface area for bacterial growth. Clear spaces between modules prevent bacterial accumulation and clogging. Percolating liquid flow is vertical or cross-current, and the slurry is lapped by naturally circulating airflow. Bioset media are easy to handle, store, and install.

Margherita Biofilm Filling Materials

Margherita biofilm filling materials are a new generation of percolator filter fills. They are made of polypropylene and have a flower shape that allows for optimal distribution within the filter. Margherita filling materials provide a high development surface area for biomass, reducing the oxygen demand of bacteria and improving wastewater treatment.Our water treatment technologies

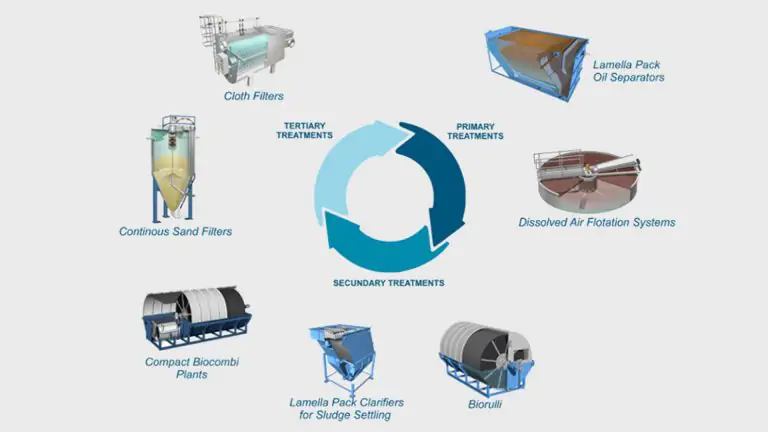

MITA Water Technologies has been designing, manufacturing and marketing treatment solutions for all wastewater, both urban and industrial, for more than 50 years of experience and an international footprint. In recent years, water reuse is gaining importance, both in the industrial and civil sectors: we are also ready for this great revolution, through our efficient and easy-to-manage solutions.

Here are our main technologies for water purification.

- Free-fiber cloth filters: an innovative solution, with very high efficiency gravity filtration for high removal yields of suspended solids. More than 600 MITA filters have been installed worldwide.

- Biodisks (or rotating biological contactors) for biological treatments: simple and reliable aerobic treatment systems.

- Compact Biocombi plants for water treatment in small communities: a space-saving solution that summarizes biological treatment and filtration. This combination ensures high effluent quality even with fluctuations in hydraulic load and solids input.

- Laminar Pack De-oilers and Decanters: our range of lamellar pack disulators and decanters offers efficient solutions for the removal of oil and grease from industrial and civil wastewater.

- Dissolved air flotation: our flotation systems are designed to treat water with high concentrations of suspended solids. Efficient separation and removal of solids.

- Continuous sand filters: simple and reliable, a solution for primary, secondary and tertiary treatments of industrial and civil wastewater.