Low investment costs. Due to the extreme simplicity of installation.

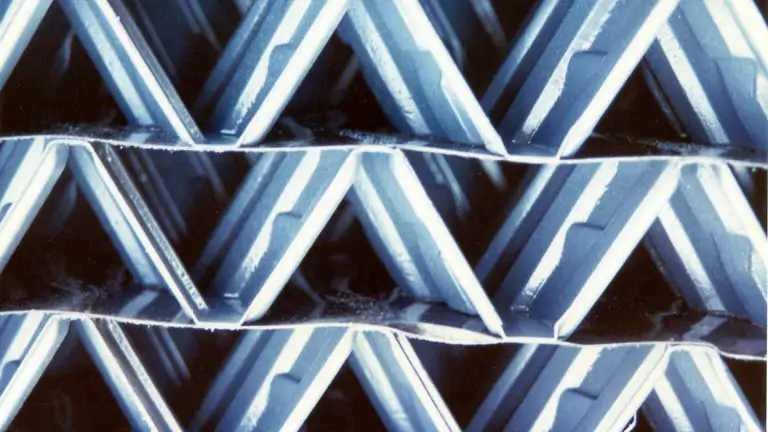

Bioset Biofilm Filling Materials

for percolating filtersBioset biofilm media consist of lightweight and robust PVC modules that provide a high active surface area for bacterial growth. Clear spaces between modules prevent bacterial accumulation and clogging. Percolating liquid flow is vertical or cross-current, and the slurry is lapped by naturally circulating airflow. Bioset media are easy to handle, store, and install.

Minimal maintenance. Biofilms tend to develop independently. This reduces operational costs over time.

Possibility of restoration of existing facilities. In many situations, biofilm media can be added to existing facilities to improve performance without having to completely replace the infrastructure.

Bioset media for biofilms: description and operation

Bioset filling materials consist of an alternating series of flat and/or corrugated PVC sheets bonded together to provide a lightweight, strong and rigid structure. Such modules are thus self-supporting and capable of bearing high loads. These structures provide a high active surface area for bacterial growth in a relatively small volume. Clearances are large enough to avoid abnormal bacterial accumulation, which could cause clogging of the filter.

The thermoformed sheets prevent free fall of the slurry evenly distributed on its top while facilitating its flow by wetting the entire useful surface with a uniform, thin film.

The percolating liquid flow is vertical or cross-current type, and it is prevented from dripping liquid directly through the entire module. Additional corrugations have been built into the molded sheets to allow easier rooting of biomass and increase local turbulence that promotes oxygen exchange between air and slurry. The slurry, containing organic residues, is lapped by a naturally circulating air flow thus providing the necessary elements for the development of bacteria on the surface of the fill.

Because of its modular structure and relatively low weight it can be easily handled, stored and installed in the tower. For supplies to distant countries it can also be transported in unglued sheets and its assembly can be carried out on site by machines easily operated even by unskilled personnel.

Ask for InformationSome MITA projects

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

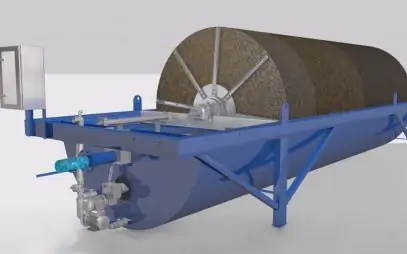

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreBiocombi Compact Systems for a Wastewater Treatment Plant

MITA Water Technologies supplied the Biocombi© BC 15/2 compact plant for biological and tertiary treatment of wastewater at the Mirabello Ciria plant.

Read more