1. Installation context

It is a pleasure to work over the years with energy companies of international stature.

Already in the past ENI, an Italian public company in the energy sector active since 1953, had requested MITA Water Technologies’ support for the supply of rotating biological contactors for wastewater treatment (through direct assignment or with an intermediary): the first order dates back to 1994.

The latest request was for not a new installation but the upgrade of a biological treatment system with Biorulli© biodiscs, delivered in 2011 and installed at the Ortona depot (Chieti province, Central Italy): average wastewater flow rate 10 m3/h, COD abatement requirement.

2. Proposed solution

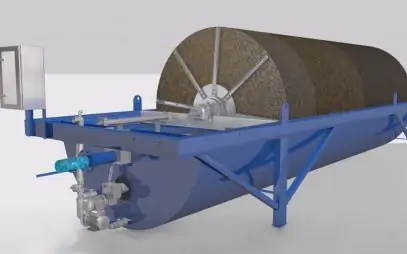

The systems supplied by MITA Water Technologies for the revamping of the water treatment section of the Ortona depot were two: a rotating biological contactor monoblock type B 200-52-1 and a similar B 200-47-1 system.

Considering the total number of plastic discs, which are technologically very simple but extremely efficient, the active surfaces of the two systems are 2,650 m2 and 2,350 m2 respectively.

Both proposed solutions are customizations of systems offered by MITA.

3. Results obtained

The main objective of the supply consisted in the reduction of COD (Chemical Oxygen Demand): goal achieved, with the abatement of about 80% of this parameter by biological treatment.

The key to success was undoubtedly the long-term relationship with the Company and the operators of the Ortona plant. In addition, also the possibility of offering solutions with off-catalog sizing: customization to the project requirement was therefore appreciated.

Ask for Information