- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

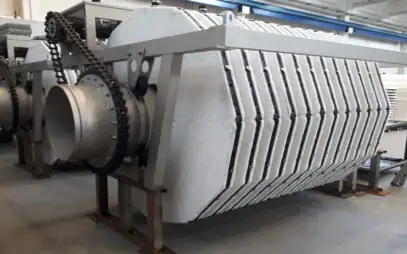

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read more