Biocombi Compact Systems for a Wastewater Treatment Plant

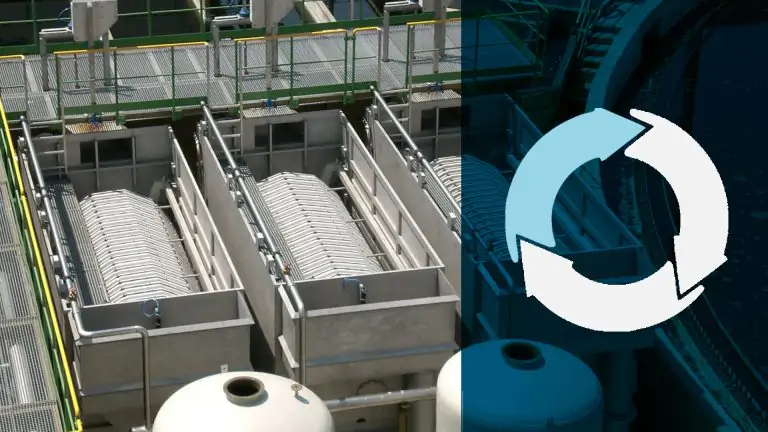

MITA Water Technologies supplied the Biocombi© BC 15/2 compact plant for biological and tertiary treatment of wastewater at the Mirabello Ciria plant.

Read more

A fining process, which refines the removal of nutrients in the effluent: tertiary wastewater treatments are particularly important processes, as they really ensure the user meets stringent regulations in terms of spills into water bodies. Many technologies in the field, including deep filtration of wastewater: high treatment yields, low resource utilization.

By tertiary treatments we refer to a series of processes that, in civil sewage treatment plants, result from the roughing out of primary treatments and the biological-type stage of secondary treatments. The purpose is the removal to higher levels of total suspended solids and other pollutants. A not insignificant effect is also the abatement of nutrient odors.

An additional function of tertiary treatments is also not emphasized enough: that of remedying any inadequacies in the primary and secondary processes. In fact, it may happen that upstream equipment carries more load to the tertiary stage technologies than expected (due to lack of maintenance, increase in unplanned effluent, design errors, etc.). Therefore, the solutions installed in this phase must be particularly efficient.

The allowable output is in the range of a few tens of mg/l total suspended solids (and consequent, additional phosphorus removal). Wastewater quality of this kind makes it possible to meet even the strictest regulations regarding spills into water bodies: to potabilize the water, however, additional processes with UV, ozonation or chlorination will be needed.

In any case, there are many areas where water reuse is possible following the tertiary phase of treatment: industry, agriculture (except for vegetable growing), and reuse for civilian use. And precisely for the purpose of reuse, the interest of tertiary wastewater treatment processes is growing all over the world: the purpose is, of course, the continuous optimization of resources and rational water management to counter certain phenomena, such as drought.

We are talking about heterogeneous methodologies, all pertaining to tertiary treatments but with their own technical and functional peculiarities: in fact, not infrequently, solutions adopting these processes are integrated with each other by technical studies.

Here is a first list of processes.

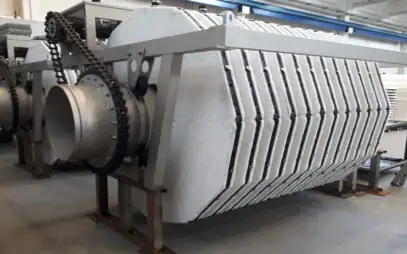

Depth filtration is one of the tertiary treatments for wastewater finishing.However, unlike micro-mesh filters, the medium for carrying out the process is a cloth with free fibers: thus, filtration takes place not on a “flat” surface but on the entire volume developed by the structure of the cloth (12 mm long threads). This allows high removal of suspended solids (and other pollutants present in the effluent).

In addition, the filtration process takes place passively: the use of electricity to operate the machine is therefore very low, being limited to the backwashing phase of the cloths in which the system moreover continues to operate.

For tertiary treatment of civil wastewater, MITA Water Technologies integrates traditional user-friendly solutions (the sand filters) and advanced filtration of free-fiber cloth technologies into its portfolio.

MITA Water Technologies supplied the Biocombi© BC 15/2 compact plant for biological and tertiary treatment of wastewater at the Mirabello Ciria plant.

Read moreMITA Water Technologies provided ESSO Italiana with wastewater treatment solutions at the coastal depots in Naples and Palermo. Through the use of continuous regeneration sand filters and Biorulli(r) biodiscs, significant results were achieved, such as reduced energy consumption and maintenance costs, plant modularity, and compliance with current regulations.

Read moreSign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.