Examples of areas: Paper production, pulp processing, paper production for other uses (packaging, printing).

Water Treatment for Paper Mills

Paper industries use a considerable amount of water, with often high values in terms of total suspended solids, BOD and COD. Some of the proposed solutions: decanters, de-oilers, oxidation systems. And for finishing, some very high-efficiency filtration solutions.

Main requirements: treatment of large volumes of water, water and waste reuse (to reduce water footprint), effluent rich in fiber and colloids, high amounts of BOD/COD.

Wastewater treatment systems for paper mills

Flowpack Lamella Decanters Monoblock FM

Solid-liquid separation, sludge decanting, water clarification for further finishing operations-all these are represented by the FM Monoblock Series lamella decanters. Compact, efficient and space-saving solution. Simplicity of operation and very low product life cycle costs are pluses appreciated by customers in the civil and industrial fields.

Biorulli® Biorotors B 200

The disc rollers, B 200 series, are the Biorulli® biodiscs biological oxidation solution: allowing high versatility in the face of widely varying effluent loads throughout the year. All this in conjunction with truly affordable acquisition costs.

Vertical-Axis Disc Filters PECV VM

An optimal solution for small and medium-sized plants, as much for its compactness as for its simplicity of installation and operation: these are the PECV VM metal tank vertical axis disc filters, for the final separation of suspended solids from civil and industrial wastewater.Characteristics of wastewater from paper mills

It is well known that the pulp and paper industry is among those that use the largest amount of the “blue resource”: some sources speak of as much as 50-75 m3 of water per metric ton of finished product. The industrial wastewater produced is therefore laden with pollutants and must be properly purified to avoid pollution of groundwater and rivers and lakes (and to avoid criminal penalties). Not only that. Given the large consumption of this industry, a water reuse system should be considered to minimize the “water footprint” and operating costs of the plants.

Paper mills produce water with high values of total suspended solids: cellulose fibers, colloids, minerals, sludge, but also heavy metal residues (such as zinc and copper). BOD (biological oxygen demand) and COD (biochemical oxygen demand) values are also often high. They therefore need useful treatments to dispose of most of the particles present and to break down the amount of organic pollutants by biological oxidation.

MITA water treatment technologies for paper mills

- Lamella-pack decanters, FM series. They operate following a gravity-based separation principle and take advantage of the use of inclined lamellae to accelerate the settling process.

- Dissolved air floaters (DAF). Their mechanical action removes high amounts of grease, preventing subsequent treatments from being inhibited.

- Lamellar-pack oil separators, OM series. The large useful surface area, allowed by the lamellae, make them an efficient and easy-to-use solution.

- Biorulli® biological oxidation systems. Easy installation and maintenance solution for removal of high BOD and COD loads.

- Free-fiber cloth filters, MSF or TF series. Very high efficiency for removal of suspended solids with outputs of a few tens of mg/l.

Some MITA projects

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

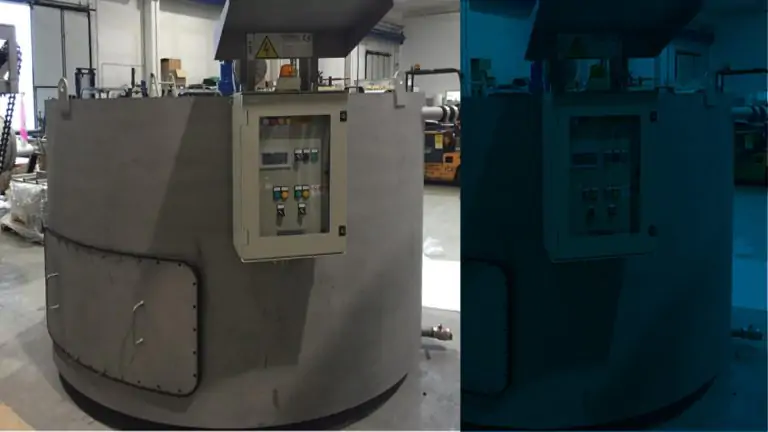

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read moreBiological Rotors for the Chemical Company Icap-Sira

High efficiency, ease of installation, and extreme operation-these are the features that a well-known company in the chemical industry appreciated in choosing Biorulli® biodiscs for the biological oxidation of its wastewater. MITA Water Technologies has been cooperating with this industry since 2006.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read more