Removal of BOD and COD: processes and technologies

There are several technologies available for the removal of wastewater organic load related to BOD and COD. For this requirement, a number of processes can be listed.

- Aerobic treatment. In this case, wastewater is brought into contact with oxygen to allow biochemical oxidation of organic matter.

- Anaerobic treatment. In contrast to the previous one, this process takes place in the absence of oxygen. It involves anaerobic microorganisms, which carry out the decomposition of organic matter.

- Chemical processes. Chemical reagents such as chlorine or hydrogen peroxide can be used to oxidize organic matter in wastewater.

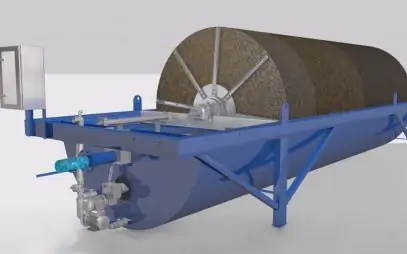

- Physical processes. When BOD/COD is in particulate form, they can be separated by gravity or mechanical separation. Sedimentation, flotation and filtration processes can then be used.