1. Installation context

MITA Water Technologies frequently works with environmental consultants for industries in different sectors: as in the case of a firm in northern Italy that, in 2022, requests our intervention for water treatment of the production processes of a client in the food sector.

The technical requirement is the abatement of COD (Chemical Oxygen Demand) and total suspended solids. The ultimate goal is the effective reuse of water in the industrial process, avoiding waste as much as possible.

Upstream of the solution being supplied, there are no treatment solutions; therefore, it is a matter of installing an entirely new system.

2. Proposed solution

Following the food company’s water analysis, MITA provides a dual solution.

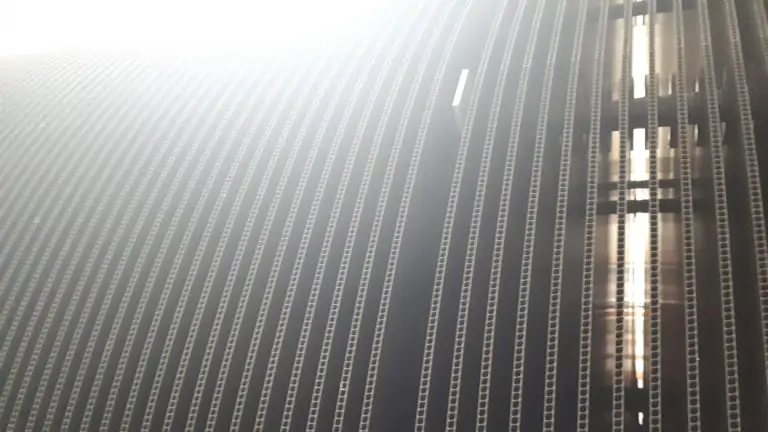

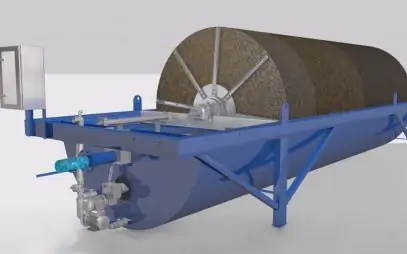

On the one hand, a system of rotating biological contactors (or biodiscs) is provided, type M 200-60-1: one-piece structure, inside a painted carbon steel tank. Disks 2.00 m in diameter, with a total usable area of 3,000 m2. Polyester cover, reinforced with glass fiber. Rotating biological contactors (or biodiscs, or rotating discs) provide a large surface area for bacterial growth, enabling COD abatement by biological oxidation. Also included in the scope of supply is a lamellar pack decanter of the FM 75-2-75 model, which allows sludge sedimentation.

Thus, the proposed solution is an integrated system: useful for the treatment of food company process wastewater in its different stages.

3. Achievements and key success factors

Not only COD abatement: thanks to the dual biodisc-decanter system, a reduction of about 80% of the input values of COD, BOD, nitrogen (N2) and phosphorus (P) is achieved.

This allows the company not only to comply with environmental regulations, but also to improve the quality of wastewater useful for its recirculation in internal processes: economic and environmental sustainability combined.

The key to the success of this provision lies in the integrated solution offering: different technologies for different stages of process water treatment. The assistance provided during start-up and testing of the system contributes to the success of the implementation.

Ask for information