Types of Water to Treat

For civil or industrial scope, for reuse and for potable water

Civil and industrial wastewater have different needs and, consequently, the mode of treatment changes.We can support you with different stand-alone situations integrated into existing plants. The important thing is to start with testing through pilot units.

Civil Wastewater

Wastewater treatment serving the community

Protecting public health and the environment is not the only purpose of civil (or municipal) wastewater treatment: in fact, the issue of reuse of the blue resource is increasingly felt by communities. A wastewater with low levels of suspended solids exiting the tertiary stage is one of the key conditions for reuse: MITA can support engineering offices and contractors with state-of-the-art filtration solutions.

Read more

Industrial Wastewater

Treatment as an opportunity for reuse

Industrial wastewater is extremely heterogeneous in quality and quantity of dissolved effluent. As a result, treatment processes and technologies vary greatly from plant to plant. MITA Water Technologies always suggests conducting tests using pilot units before selecting the best available solution.

Read moreDrinking Water

How we support the process for potabilization

Two solutions are often used for the final treatment of water and its consumption by humans: reverse osmosis membranes and UV disinfection. And these two technologies, in turn, can find an ally in free-fiber cloth filters. The goal: effective removal of suspended solids pre-potable.

Read more

Our Range of Products

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

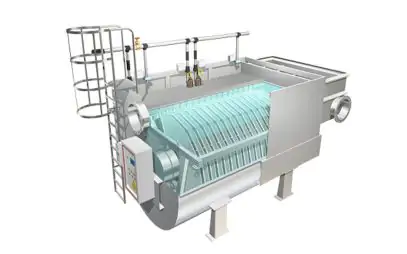

Pile Cloth Filters

for tertiary wastewater treatmentVery high suspended solid removal rates and minimal product life cycle cost: these are the advantages of pile cloth media filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

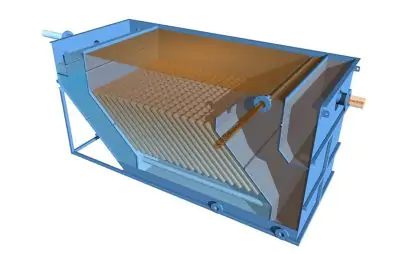

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

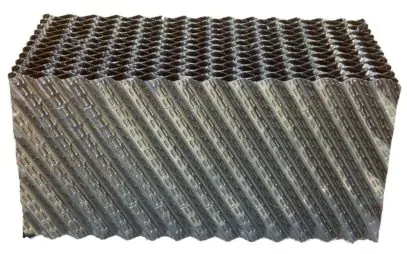

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

Wastewater: the different types at a glance

Different needs, different treatments: in the appropriate sections you can find more information about the different solutions used for different types of water. Here you can find a first summary, however.

- Civil wastewater. They are conveyed to public plants from the wastewater of an entire community: therefore all treatment stages (primary, secondary, tertiary) are carried out sequentially as required by national and transnational laws. From roughing to finishing. The goal is proper re-injection into water bodies and, in some cases, reuse and potabilization.

- Industrial wastewater. Unlike the civil sector, each plant is its own species: some lines produce water that only needs finishing by filtration, others have significant amounts of suspended solids, BOD and COD in output (and require at least biological treatment). In some cases, stand-alone solutions can be installed; in other situations, several treatments are needed in sequence. For all these reasons, in industrial settings it is even more important to start with water testing using pilot units.

- Drinking water. The most rigorous treatments must be carried out to produce potable water. Technologies such as reverse osmosis and UV lamps are used to produce this highest quality output. And cloth filters are also often integrated downstream of these systems to “lighten” the incoming load of suspended solids.

What is your process goal?

Tools to help you choose

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.