Vertical Cloth Filters: Tertiary Filtration for Small Footprint

In 2020, European Directive 2184 established what amount of suspended solids must be present at the discharge in order not to incur penalties: 10 mg/L for tertiary treatment. Will these be the final values? Will national legislations decide to apply more stringent criteria?

Undoubtedly, wastewater treatment will represent an opportunity for those who can seize the opportunity for efficient reuse to optimize their internal processes. But also a major challenge, for those who find themselves equipped in production spaces with no previously dedicated surfaces.

Stringent regulations, tight spaces, tight installation budgets and future shortage of the water resource: what is the optimal system for engineering firms and environmental consultants facing these challenges? In many municipal, but especially industrial installations, versatile vertical cloth filters are the answer.

Let’s see why.

1. Horizontal or vertical cloth filters? A bit of history

Let’s do a bit of history and contextualize the need for tertiary filtration with vertical filters.

Horizontal-axis free-fiber cloth filters were invented in the 1970s as a tertiary filtration system for water finishing of municipal and industrial wastewater treatment plants. Their plus? It is the filtering cloth: in fact, the long, disassembled filaments of this material allow significantly more efficient volume filtration than the surface filtration of micro-mash.

Starting in the 1990s, free-fiber cloth filters became a popular system for the final stages of wastewater treatment, particularly when advanced removal of total suspended solids is required.

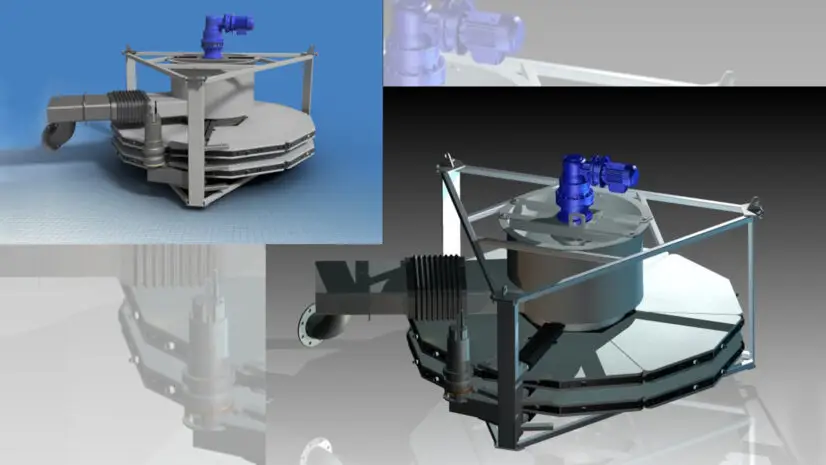

The large-scale diffusion of cloth filtration is accompanied by constant technological innovation aimed at obtaining increasingly efficient machines with smaller and smaller footprints. It is in this context that in 2010 the team at MITA Water Technologies created the first vertical-axis free-fiber cloth filter: the discs, installed on a tank with a diameter of only 2.5 m, are mounted on a vertical shaft, allowing optimization of the use of available space. Of course, the reduction in footprint was achieved while maintaining the solids removal performance provided by horizontal systems.

Currently, vertical cloth filters are widely adopted both in municipal sewage treatment plants, particularly small ones, and, most importantly, in industries around the world.

2. How do vertical cloth filters work?

Vertical cloth filters operate by gravity and use discs covered in filter cloth to remove suspended particles in water. The process can be divided into a series of contextual steps:

- Feeding: the water to be treated is fed into the filter housing tanks and passes through the filter media from outside to inside (out-in motion).

- Filtration: Suspended solids retained by the filtering cloth accumulate on the outside of the discs and form a layer of sludge.

- Treated resource outlet: the purified water passes radially through the discs and is collected in the hollow shaft. Once through the rising channel, it is conveyed to the next treatment stages or sent for reuse.

- Backwashing: to maintain filtration efficiency, the filter automatically performs backwashing cycles: a flow of treated water is passed counter-currently through the cloth (in-out motion), thanks to a system of suction pumps. This flow removes the layer of sludge deposited on the outer surface of the discs by shaking the fibers and releasing the solids trapped in the cloth: they are then removed from the system. During backwashing, filtration is not interrupted.

3. Advantages: versatility and convenience at the highest level

Vertical cloth filters are thus distinguished by their versatility. The following are the main advantages of the system.

- Small footprint: their compact design requires minimal installation area, making them ideal for tight spaces.

- Scalability: the initially installed filter surface area can be increased later (by adding discs) to ensure the treatment of any surplus water resulting, for example, from future expansions.

- Easy integration into the installation context: the vertical disc filter system is a plug & play one, so it can be supplied complete with every accessory needed for operation.

- Additional ancillary works not required: unlike other systems, installation is quick and requires only the making of the plumbing and electrical connections. Expensive and laborious excavations are not required.

- Cost-effectiveness: for the same filter area, vertical cloth filters are significantly more cost-effective than horizontal systems.

- High filtration efficiency: as in the case of horizontal cloth filters, even the finest suspended solids can be retained with high efficiency thanks to the free-fiber.

- Easy maintenance: vertical cloth filters are “simple” systems with minimal maintenance requirements; cleaning operations are simple and quick.

- Reduced energy consumption: electricity is used only during the backwashing phase: an advantage shared with the similar horizontal-axis solution.

- Protection of ecosystems: wastewater treated with cloth filters can be discharged into rivers or other water bodies without incurring penalties, thanks to the high removal capacity of suspended solids.

- Optimizing production processes: thanks to effective water reuse, cloth filters are an excellent treatment system to contribute to more rational and efficient production (both environmentally and economically).

4. Technical data and performance

MITA Water Technologies’ vertical filters can mount up to 6 discs, each having a filtering area of 5 m2: up to 30 m2 of cloth for removal of suspended solids. Downstream of physical-mechanical and biological treatments, a vertical disc filter system can meet treatment needs of up to 15,000 AE, which is a small town.

Used for the treatment of both municipal and industrial water, this technology makes it possible to achieve concentrations of total suspended solids at the outlet even lower than 5 mg/L: values suitable for compliance with the various legislations for the discharge of effluent into water bodies.

In MITA vertical disc filters, backwashing of the cloth is carried out by means of pumps that are automatically activated by the PLC without interrupting filtration. Energy use is minimal because the electrical consumers are active only during the backwashing phase.

5. What are the applications of vertical cloth filters?

Vertical cloth filters are therefore suitable wherever a final filtration stage is required with small installation spaces and treatment needs in the range of thousands of population equivalents.

Examples include:

- municipal wastewater treatment,

- plastics industry,

- food & beverage industry,

- steel plants,

- chemical and pharmaceutical industries.

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.