Very high filtration yields. Due to the depth filtration of the free-fiber cloth. TSS concentrations up to 5 mg/l expected at discharge, depending on application.

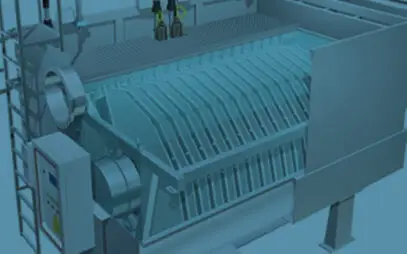

PEC - PEC VM Rotary Disc Filters

filter area from 10m² to 160m²With these free-fiber filtration systems, we get to serve medium to large sewage treatment plants with minimal floor space requirements. Not only that. In the PEC and PEC VM disc filters, backwashing with sequentially driven pumps provides the machine with operational continuity in wastewater treatment, consequently avoiding the need to provide a back-up unit.

Reduced energy use. Gravity filtration, power consumption only in backwash phase.

Operational continuity. Filtration is continuous during counter-current cloth washing.

Flexibility with different loads. Self-adjustment according to input parameters.

Easy maintenance. Simplicity and reduced frequency of intervention.

Minimum life cycle cost. Low investment (CAPEX), maintenance and resource utilization (OPEX) costs result in optimal return on investment.

PEC and PEC VM Rotary Cloth Disc Filters: available versions

Basic Version

Backwash works with only one pump at a time-an additional energy saver.

HD version

Backwash works with one or two pumps at a time: great versatility of operation.

FHD Version

Backwash works with only two pumps at a time: fast and efficient tele-washing.

PEC and PEC VM water filtration disc filters: system description

With cloth filters in general, and with PEC and PEC VM discfilters in particular, depth filtration similar to that of sand filters is achieved both in terms of mode of operation and suspended solids removal yield.

The largest model in this series has a number of discs equal to 32, a filtering area of 160 m2 with a floor space of only 20 m2. On the industrial side, companies can choose PEC and PEC VM filters for industrial pre-spill process water finishing in rivers and lakes or pre-use.

The peculiarity of the PEC – PEC VM series (especially in comparison with PPC – PPC VM, which have similar structural features) is in the backwashing of the plies: the pumps, each of which is slaved to three or four discs, are operated sequentially, so that the functionality of the system is never interrupted.

The PEC – PEC VM solution responds particularly flexibly and reliably in cases of unmanned plants with high and extremely variable loads. The different models available can be installed in parallel, thus realizing plants of various capacities. Two versions are available: for installation in concrete tank (PEC) and with metal tank (PEC VM).

Ask for Information

BIM Files

Download PEC Disc Filters on Skeinforce| Model | Disc dimension [mm] | Number of discs | Filtrant surface [m2] |

|---|---|---|---|

| MSF 2/10 PEC | 2100 | 2 | 10 |

| MSF 3/15 PEC | 2100 | 3 | 15 |

| MSF 4/20 PEC | 2100 | 4 | 20 |

| MSF 6/30 PEC | 2100 | 6 | 30 |

| MSF 8/40 PEC | 2100 | 8 | 40 |

| MSF 10/50 PEC | 2100 | 10 | 50 |

| MSF 12/60 PEC | 2100 | 12 | 60 |

| MSF 14/70 PEC | 2100 | 14 | 70 |

| MSF 16/80 PEC HD | 2100 | 16 | 80 |

| MSF 18/90 PEC HD | 2100 | 18 | 90 |

| MSF 20/100 PEC HD | 2100 | 20 | 100 |

| MSF 22/110 PEC HD | 2100 | 22 | 110 |

| MSF 24/120 PEC HD | 2100 | 24 | 120 |

| MSF 24/120 PEC FHD | 2100 | 24 | 120 |

| MSF 28/140 PEC FHD | 2100 | 28 | 140 |

| MSF 32/160 PEC FHD | 2100 | 32 | 160 |

Case studies with cloth filters

Cloth Filters and Cooling Towers for Plastic Industry

Cooling and wastewater treatment together: that's the card that proved successful in supporting a plastics equipment company in northern Italy, which was already working with MITA Cooling Technologies (now a commercial partner of MITA Water Technologies). The possibility of water reuse, through comprehensive management of this resource, is a card that industries can exploit to derive value from blue gold.

Read moreCloth Filters for the Cuma Wastewater Treatment Plant

It is one of the largest tertiary filtration systems in Europe: the MITA supply for the vast Cuma water treatment plant near Naples, having a treatment capacity of 1,200,000 population equivalents. The goal of the project was to improve the plant's purification performance.

Read moreTools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.