1. Installation Context

The case study concerns a water recycling centre located in North Norfolk, United Kingdom, which serves an estimated population of about 7,600 residents. This facility faces the need to adapt to new and more stringent regulations imposed by the UK’s Environmental Agency, aimed at improving the quality standards of the water released into the environment. The intervention is part of the “AMP8 Habitats” scheme, under AMP7’s Accelerated Infrastructure Delivery (AID), with the primary objective of achieving nutrient neutrality in the treated and discharged water.

The main challenge for the water recycling centre is the significant tightening of the discharge limits for phosphorus. Previously, the permitted limit was 1 mg/l, but the new directives drastically reduce it to 0.25 mg/l. In addition to phosphorus, the project aims to control iron levels, with a discharge target of less than 4 mg/l, and total suspended solids (TSS), which must be kept below 5 mg/l (at the 95th percentile). Upgrading the plant is therefore crucial to ensure regulatory compliance and minimize the environmental impact of treated wastewater, protecting local aquatic ecosystems.

The implementation of advanced solutions is essential to overcome these technical and operational challenges, allowing the water recycling centre to operate sustainably and in compliance with the latest environmental laws, thereby safeguarding the region’s biodiversity.

2. Proposed solution

To address the complex upgrade requirements of the water recycling centre, ATAC Solutions, part of the Axius Water group along with MITA Water Technologies, designed and implemented a customized solution.

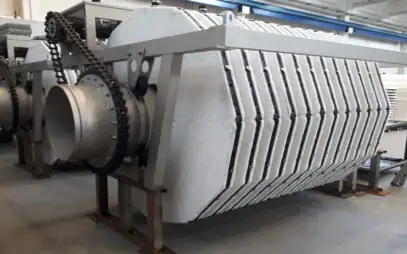

The proposal involved the installation of two MITA WT cloth filters, chosen based on detailed process calculations and comprehensive technical data sheets. The selection of the 12/60 cloth disc filter model was strategic, not only for its high tertiary filtration capabilities for solids removal but also because it guarantees system redundancy: if one filter were to go out of service, the other can continue to operate, ensuring the continuity of the wastewater treatment. This feature is fundamental for plants of such importance, where service interruption can have significant repercussions.

The project parameters for implementation included an average flow rate of 72 l/s and a maximum feed flow rate of 103 l/s. The solution was sized to handle an inlet total suspended solids (TSS) concentration of 25 mg/l (including chemical products) and a peak TSS load of 14.1 kg/h.

The project execution presented some unforeseen challenges, particularly related to the routing of cables from the control panels to the equipment (drum motors, probes, backwash skids, and pressure transducers). As these had not been designed in advance, the team had to devise and build these routes on-site, adding complexity to the installation process. Nevertheless, the experience and professionalism of ATAC’s in-house project team made it possible to overcome these obstacles, maintaining the effectiveness of the intervention.

3. Results and key success factors

The upgrade project at the North Norfolk water recycling centre is currently in its final stages of completion. The last phase involves the installation of the dosing system, after which the system will be able to operate in a fully automatic mode, ensuring optimal efficiency and a reduced need for manual intervention.

The main objective of this installation is to enable the water recycling centre to meet the new and rigorous water quality standards imposed by the Environmental Agency, particularly regarding the reduction of phosphorus, iron, and total suspended solids (TSS) levels. It is expected that the plant will be able to consistently achieve the required discharge limits, with total phosphorus below 0.25 mg/l, iron below 4 mg/l, and TSS below 5 mg/l.

The key success factors of this project include the accurate design and detailed calculations that guided the selection and sizing of the filters, and the strategic choice of a technology that ensures redundancy and high performance in the removal of total suspended solids. ATAC Solutions has installed two MITA disc filters (Model 12/60), ensuring redundancy and high performance.

The project, now in its final phase, will allow the plant to achieve its effluent quality and environmental compliance goals, demonstrating the effectiveness of advanced filtration solutions for the protection of the territory and the communities it serves.

Ask for Information