1. Context of Installation

A regional council in South East Queensland, Australia, had to address a critical issue at the Imbil wastewater treatment plant. The existing system, based on rotating biological contactors (RBCs), was obsolete and its performance had severely deteriorated. Designed to treat settled sewage but without adequate pre-screening, the RBCs were no longer able to operate optimally.

This inefficiency resulted in non-compliance with license conditions and effluent quality standards, posing risks to the local ecosystem and potential penalties. Operating costs had increased due to frequent maintenance and higher energy consumption. Therefore, a complete revamping of the system was necessary, which would replace the obsolete units, improve the pre-treatment of raw water, and ensure long-term efficiency and resilience. The solution needed to be compact and integrable with the existing infrastructure.

The goal was to restore the full functionality of the plant, ensuring high-quality effluent, reducing environmental impact, and optimizing costs.

2. Proposed solution

To meet the needs of the Regional Council, MAK Water, the distributor of MITA Water Technologies in Oceania, was chosen. The solution strategically combined advanced technologies to overcome the limitations of the previous system, while respecting the site’s constraints.

The first phase involved the installation of a mechanical inlet screen upstream of the process, with a capacity of 108 m³/h and 5 mm perforations, to remove coarse solids from the raw wastewater. This pre-treatment was crucial for protecting the downstream equipment, preventing blockages and wear.

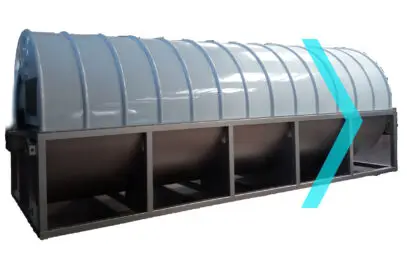

The core of the solution was the implementation of two new Biorulli® rotating biological contactors (RBCs) from MITA Water Technologies, replacing the six obsolete units. These aerobic biological oxidation systems utilize the growth of a biofilm on rotating discs partially submerged in the sewage. The slow rotation alternately exposes the biofilm to the water and the air, promoting the degradation of pollutants. This technology offers great flexibility with respect to load variations, low energy use, and a rapid startup, usually within 10-15 days. Their compactness allowed for easy installation in the existing spaces. MAK Water provided a pre-assembled solution, minimizing on-site construction time.

3. Results and key success factors

The intervention by MAK Water led to remarkable results for the Imbil plant. The new Biorulli® units reached full operation in just 15 days from startup, without the need for bacterial inoculation. This allowed for the rapid restoration of the plant’s functionality.

The new system ensured regulatory compliance, with the treated effluent consistently exceeding the required quality standards (maximum BOD5 of 20 mg/L), eliminating the risk of penalties and protecting the environment.

From an economic point of view, operating costs were drastically reduced. The energy consumption of the Biorulli® proved to be very low, with significant savings on operating costs. The simplicity of management and minimal maintenance further lowered expenses.

The operational flexibility of the Biorulli® was a key factor, demonstrating insensitivity to hydraulic load variations and a rapid recovery of performance. The approach with pre-assembled equipment reduced installation times. This combination of efficiency, low costs, robustness, and ease of implementation has made the solution from MAK Water and MITA Water Technologies a successful model for municipal wastewater treatment.

Ask for Information