1. Context and problem

The wastewater pumping station (WPS) at a trial site in North Hampshire is regularly affected by groundwater infiltration, a problem that is particularly acute during periods of heavy rain and storm events. This situation poses a significant flood risk to the downstream villages. One of the main strategies adopted to mitigate these risks, related to groundwater infiltration and combined sewer overflows (CSOs), is over-pumping, which involves releasing excess water into the local watercourse when the pumping station cannot handle the high flow volumes.

During an over-pumping event, it is crucial to minimize the risk of contamination to the watercourse. Initially, at the trial site, the excess flows underwent a screening process and then UV light treatment before being discharged into the stream. However, discharge was only permitted when the aquifer water levels reached a predetermined level, a condition that was often not met. Consequently, it was necessary to resort to the use of 24/7 tanker trucks for water management, rather than being able to discharge it directly into the stream.

The water company, as the service operator, aimed to improve the quality of the discharge by removing suspended solids and the associated concentrations of BOD (Biological Oxygen Demand) and NH3 (Ammonia) from the effluent before its release into the watercourse. Furthermore, a strategic advantage of implementing a cloth filter would be the improvement of the effluent’s transmissivity, essential for allowing the UV treatment to achieve greater bacterial elimination and higher efficiency in coliform reduction. The type of effluent in question, resulting from groundwater infiltration causing the combined sewer system to overflow, is typically very diluted—a context in which MITA cloth filters had not been commonly used before. Therefore, the primary purpose of this specific test was to evaluate the performance of the cloth filter on this particular type of effluent, with the objective of testing different types of filter media and analyzing the results under various hydraulic and solids loading conditions.

2. Proposed solution

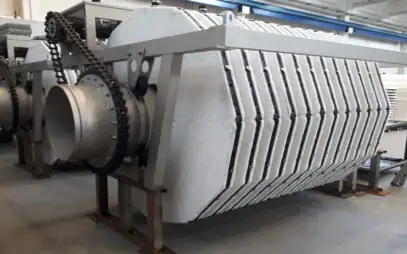

ATAC Solutions responded to the water company’s needs by proposing the installation of a MITA PECV 4/20 cloth filter, a vertical-axis model designed for space and efficiency optimization. The solution involved positioning the filter between the existing screening and UV treatment stages, with the goal of intercepting and treating the effluent after screening and before disinfection.

The initial phase of the project saw ATAC Solutions conduct a detailed site survey to assess the feasibility of the installation and gather all necessary information. During this visit, ground levels were measured to ensure the hydraulic system could operate effectively. The MITA 4/20 filter was then installed on railway sleepers, placed on a level Type 1 base adjacent to the station’s main electrical panel (MCC). This arrangement allowed the filter to be raised by 200 mm, ensuring that the filtered water could discharge by gravity directly into the UV equipment, eliminating the need for additional pumps that would have required diesel or electrical power.

The inlet of the MITA filter was connected directly to the discharge pumps of the existing screening equipment via a flexible Bauer hose. This design choice simplified the installation process and contributed to operational efficiency. For the discharge, the MITA filter outlet was connected to PVC piping supported by appropriate stands, allowing a free flow by gravity towards the UV unit. A fundamental safety measure was also implemented: the cloth filter’s overflow pipe was connected to the outlet pipe leading to the UV equipment, creating a failsafe system for the filter. The filter’s backwash, an essential process for its cleaning and long-term efficiency, was managed via a flexible Bauer hose that discharged the backwash water directly into the pumping station’s collection tank (wet well). This temporary configuration was carefully designed for a trial period, with the intention of specifically evaluating the performance of the MITA cloth filter on an atypical effluent, characterized by its high dilution due to groundwater infiltration. The goal was not only to verify its immediate effectiveness but also to collect valuable data for potential future installations and for the optimization of the system under variable operating conditions.

3. Results and key success factors

The sampling process at the test site was conducted over a period of 7 days between June and July, with tests on various parameters both before and after treatment. The results demonstrated the remarkable effectiveness of the MITA PECV 4/20 fabric filter in improving effluent quality.

The3. Results and key success factors

key evaluation parameter, total suspended solids (TSS), showed a significant improvement. With an average inlet concentration of 43.6 mg/l, the filter reduced TSS to an average of 9.6 mg/l at the outlet, achieving an average removal rate of 76.6%. It is important to note that removal levels never fell below 70% during the entire test period, demonstrating the reliability of the filter even under high load conditions. On one occasion, when the inlet concentration exceeded 100 mg/l, the filter still removed 79.5% of the solids.

The high efficiency in removing TSS also had a positive knock-on effect on the BOD (Biological Oxygen Demand) and COD (Chemical Oxygen Demand) levels in the effluent. Before treatment, the average BOD and COD values were 32.1 mg/l and 80 mg/l, respectively. After treatment with the cloth filter, these values were reduced to an average of 15.4 mg/l for BOD and 30.6 mg/l for COD. This represents a reduction of more than 50% for both parameters.

Another crucial success of the test was the improvement in the performance of the downstream UV treatment. The UV treatment stage showed a reduction in E. coli and Enterococcus species of approximately 99.99% (equivalent to a reduction of approximately 3 log), thanks in part to the increased transmissivity of the post-filter effluent. As expected, no significant reductions in ammonia, nitrate, nitrite, or phosphate were observed during the trial period, as no specific treatment stages were planned for these parameters.

In summary, the test results clearly demonstrated that the MITA cloth filter is a highly effective solution for significantly reducing suspended solids and associated BOD and COD concentrations in combined overflow wastewater. This system has proven to be a proven method for treating storm water or groundwater discharges from overloaded pumping stations, reducing the environmental impact on local waterways. Although the trial period was limited and conducted during dry weather conditions (June and July), the success achieved has strengthened confidence in the ability of these filters to be installed at other sites with similar issues to the trial site. The water company is actively involved in proposing the use of these systems, including cloth filters, for future groundwater treatment.

Ask for information