1. Installation context

Large industries in the food sector, with heavy use of process water for processing their products, have long understood the importance of treating and reusing the “blue gold”-an environmentally and economically sustainable decision to which tertiary filtration provides an answer.

In 2018, the management of a prestigious multinational brewing company decides to optimize the reuse of wastewater from one of its Vietnamese plants: a contractor is brought in for this.

The plant is known for its water efficiency: the process lines use only 2.32 liters of water to produce one liter of beer, including that contained in the beer itself. In addition, 8 percent of the water used was recovered and used for cleaning purposes in the plant. This is also due to the fact that a wastewater treatment plant is already in place and active. Its components: complete biological treatment, additional treatment for phosphate removal by coagulation-flocculation with alum (aluminum sulfate) and polymer, clarification for removal of suspended solids, and reverse osmosis using membranes.

However, the need to add a continuous, uninterrupted tertiary filtration unit for removal of suspended solids upstream of the membrane section is noted. The solids to be abated are a mixture of activated sludge flocs and precipitated aluminum phosphate/hydroxide flocculated with polymer. Average flow rate: 258 m3/h.

In addition, the new installation will have to ensure good performance so as not to send the membrane system, which is present downstream, into failure.

2. Proposed solution

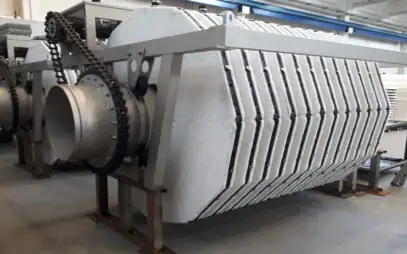

The contractor involved by the brewing company turns to MITA Water Technologies for the supply of a fleece filtration system. Process water analysis is carried out through pilot units as per practice, and then an MSF 8/40 PEC system is selected: 8 discs for a total filtering surface area of 40 m2, “classic 10” fleece.

The filtration system provides continuous and uninterrupted filtration, with automatic backwashing to ensure optimal performance. Treated water is then discharged through a central pipe to the adjacent compartment with overflow. The overall dimensions only small, the use of electricity is limited to the backwashing phase of the suction cloths.

3. Results and key success factors

Cloth filters achieve the required performance. In addition, due to the removal of suspended solids, a reduction in phosphorus in wastewater is also noted, thus contributing to overall nutrient management.

Low performance and consumption. The goal of optimizing the reuse of process water is achieved, contributing to the water efficiency of the plant with a view to environmental and economic sustainability.

Ask for Information