A single interlocutor. Your partner throughout the project and installation, whether for individual solutions or turnkey refrigeration systems.

Refrigeration Systems for Operations Managers

Rely on simple solutions, you can concentrate on production

The ideal industrial chiller or cooler is one that you can install and then... forget about. We have implemented several specifications to align ourselves with this 'ideal' and offer plant managers the coveted operational continuity: design with advanced programmes, repeated tests on all refrigeration systems or further machines, accessories for Industry 4.0. Furthermore, we aim to be the single point of contact for those managing complex systems.

Selected internal components. Evaluation through unified programmes to have immediate visibility of their interaction in the design phase.

Predictive maintenance. All Frigofluid systems have Industry 4.0 Certification and can therefore be monitored remotely at the customer's request.

Guaranteed performance. Regular testing and acceptance of all installed solutions.

Safety in operations. Chillers, coolers and temperature controllers regularly tested before installation, rigorous after-sales service with licensed refrigeration technicians.

References in industry. We have been serving a variety of industries since 1995, thanks to the decades of experience of our founding partners.

Simple and reliable refrigeration

In most plants, refrigeration and cooling systems are the final section of a long production line: what operations managers want is to take complexity out of the system, to focus on productivity. And to rely on a single, reliable contact for the individual parts of the plant.

This is why the regular test and acceptance phase for all machines is important: each component, already selected in its interaction with the other parts, is individually checked. All this to ensure operational continuity for plant managers, at least as far as the refrigeration section is concerned.

The security of Industry 4.0

Remote monitoring is a further tool for ensuring operational continuity: Industry 4.0 chillers and chillers allow real-time verification of performance and correct operation, with the possibility of timely intervention if the operator notices unexpected parameters.

All Frigofluid devices have Industry 4.0 Certification issued by Bureau Veritas. The operations manager can therefore request the appropriate service to integrate the refrigeration (or cooling) system with his company management system and obtain the benefits of this extraordinary innovation.

Customer care services you can count on

Ordinary maintenance is an important moment to have your technology always efficient and safe and to allow the regular operation of the whole system: it must therefore become a ‘habit’ thanks to the support of refrigeration technicians, all of whom have a regular licence.

Frigofluid is able to guarantee this service: the company’s mobile workshops are perfectly equipped for this purpose. You can also count on the training of your operators, so that you know when to ‘service’ your machinery.

A separate chapter is the management of F-Gas in industrial chillers: we can repair and maintain chillers containing fluorinated greenhouse gases. With our F-Gas certification issued by Apave, an Accredia-certified body, we intend to stay in line with the latest updates of the F-Gas directives.

Ask for informationOur range of wastewater treatment systems

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

Pile Cloth Filters

for tertiary wastewater treatmentVery high solids removal yields and minimal product life cycle cost: these are the advantages of pile cloth filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

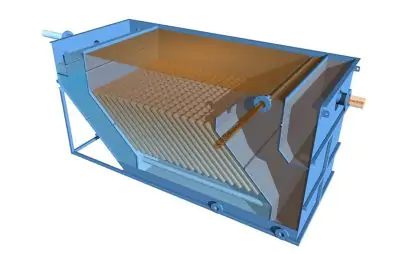

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

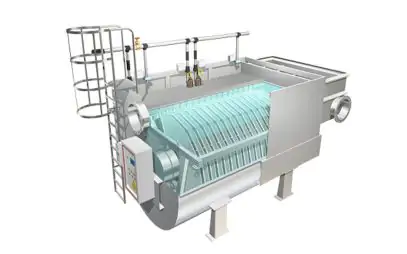

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

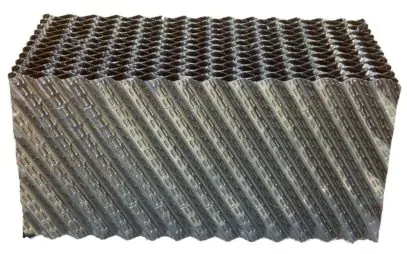

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.