Efficiency in separation. Flap pack oil separators are very effective in separating oils and light hydrocarbons precisely because of the 45-degree inclined lamellae within the system.

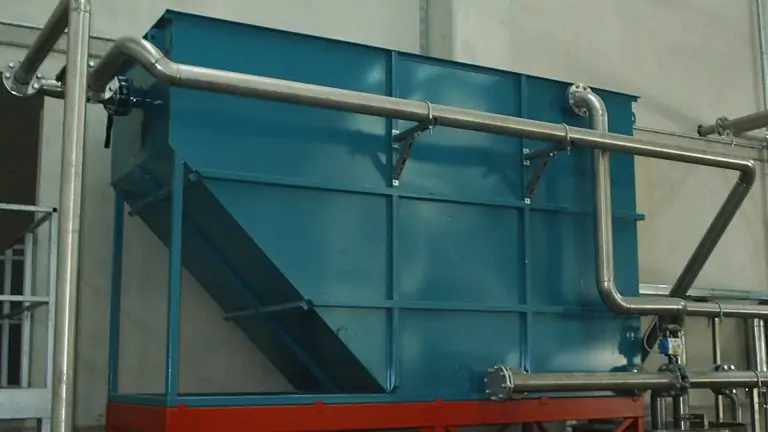

Oilpack Oil Separators Monoblock OM

for the separation of oilsThese one-piece oil separators are designed to separate non-emulsified oils and consist of a containment tank, made of treated and painted carbon steel or AISI 304 stainless steel or stainless steel according to the customer’s choice, and a 45° inclined parallel channel lamella pack made of UV-resistant polystyrene. Customizations with special materials are available upon request.

Compact design. Lamella pack oil separators do not require large pools or tanks and are therefore suitable for installations in confined spaces: for example, parking lots, machine shops and industrial areas.

Oil recovery. Following separation, oil separators can recover the separated oils and light hydrocarbons to enable easy recycling or disposal.

Oilpack Monobloc OM lamella pack oil separators: description and operation

These are one-piece lamellar pack oil separators for the separation of non-emulsified oils.

They consist of: containment tank that can be made of either treated and painted carbon steel or AISI 304 stainless steel or stainless steel according to the customer’s choice; lamella pack with parallel channels inclined at 45° made of rigid polystyrene stabilized against UV rays. Special materials and executions are available upon request.

Some of the typical applications:

- first rainwater from yards,

- petrochemical industries,

- machine shops,

- refineries and hydrocarbon depots,

- vehicle washing,

- reclamation,

- ecological platforms.

Some MITA projects

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read moreBiological Rotors for the Chemical Company Icap-Sira

High efficiency, ease of installation, and extreme operation-these are the features that a well-known company in the chemical industry appreciated in choosing Biorulli® biodiscs for the biological oxidation of its wastewater. MITA Water Technologies has been cooperating with this industry since 2006.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreWhat is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.